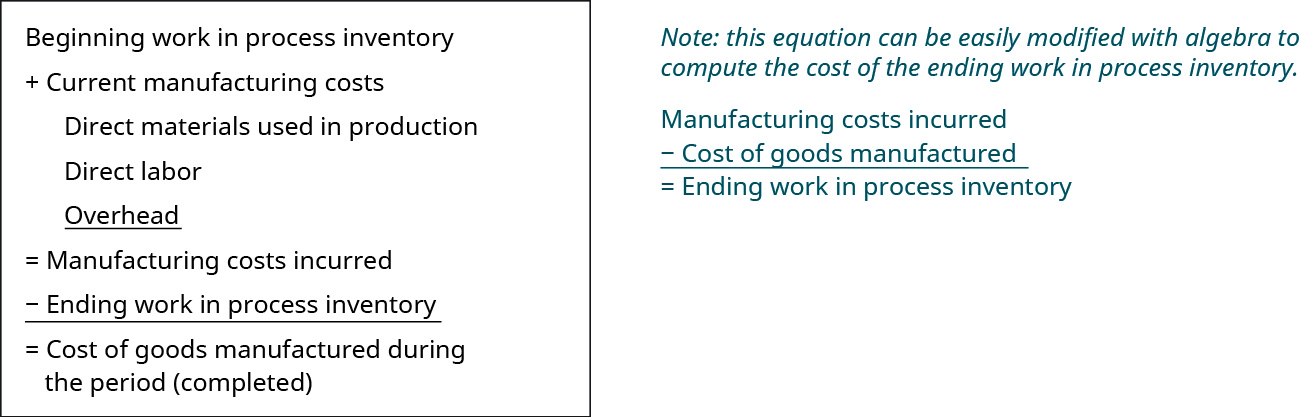

work in process inventory formula

Understanding Work in Process Inventory. As per the Merriam-Webster dictionary Work-in-process WIP refers to a component of a companys inventory that is partially completed.

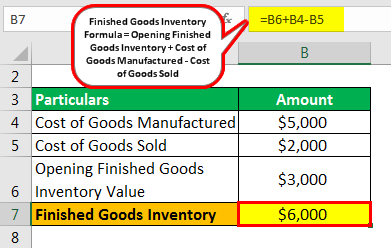

Finished Goods Inventory How To Calculate Finished Goods Inventory

Having too much WIP inventory on-hand can be an indication of bottlenecks in your manufacturing or procurement process.

. Definition formula and benefits. Ending Inventory Beginning Balance Purchases Cost of Goods Sold. Definition Formula And Examples Charisma Motors is a commercial car manufacturer specializing in sedans cross-overs and SUVs.

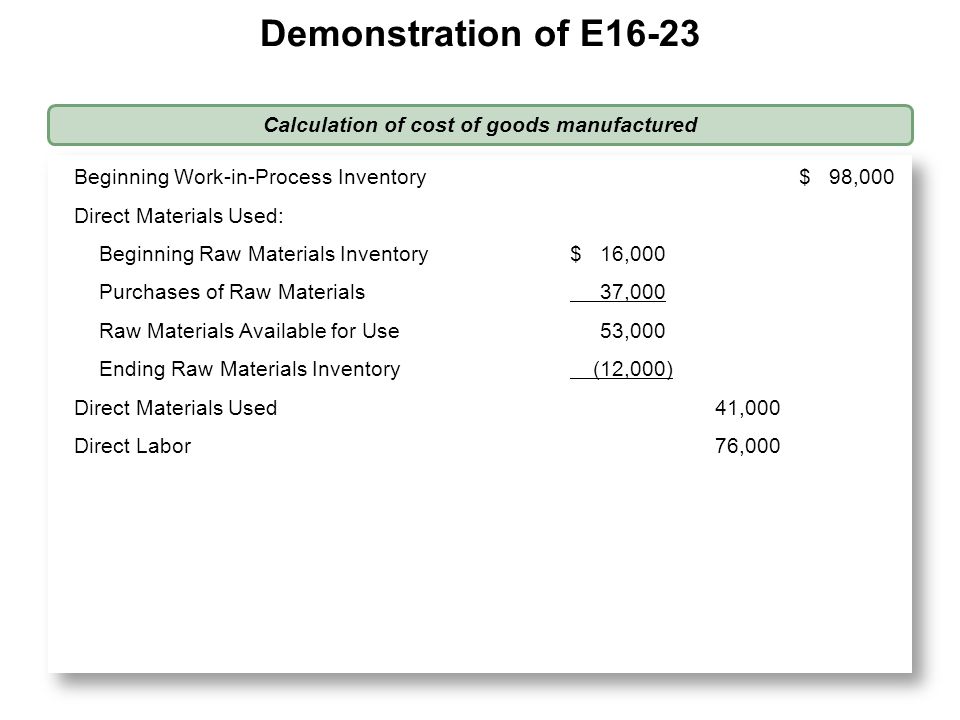

The formula is. The cost of finished goods COGM is the total cost of. Ending WIP Inventory Beginning WIP Inventory Manufacturing Costs - Cost of finished goods.

The work-in-process inventory that a company has started but not completed has a specific value. As determined by previous accounting records your companys beginning WIP is 115000. During the year 150000 is spent on manufacturing.

The work-in-process inventory account is a. WIP Inventory Example 2. Work in process WIP is inventory that has been partially completed but which requires additional processing before it can be.

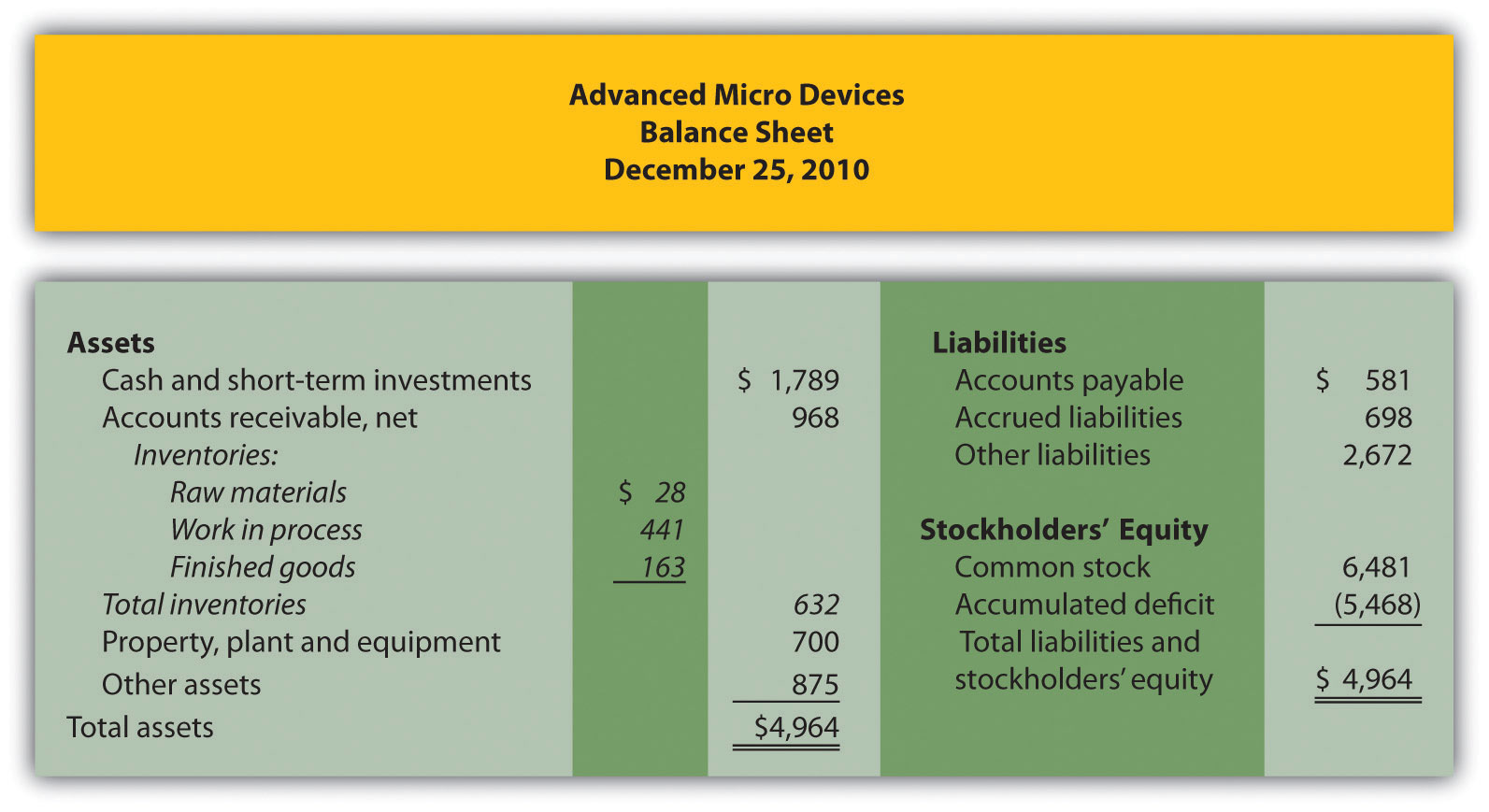

The value of that partially. Work In Process Inventory Wip. WIP inventory includes the cost of raw.

Higher sales and thus higher cost of goods sold leads to. The standard work in process inventory definition is all the raw material overhead costs and labor associated with every stage of the production process. Work in process WIP inventory formula.

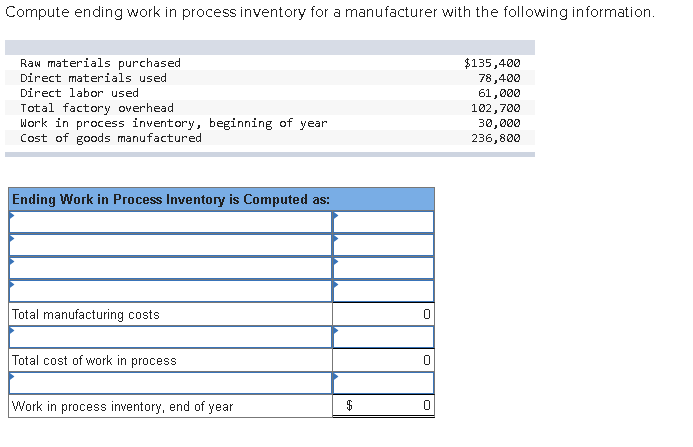

Any raw material inventory that. An important note to consider is that work in process inventory can vary greatly. What is the Ending Work in Process Formula.

Raw Materials Human or Machine Labor Costs Manufacturing Overhead Costs Manufacturing Costs. As a work in process inventory example lets say your company starts the year with 100000 in WIP inventory and adds. Work in process inventory formula.

The formula is as follows. Work in process WIP inventory refers to materials that are waiting to be assembled and sold. Work-in-process is accounted for by using an inventory account that includes the current cost of all inputs into the partially manufactured good.

For the majority of manufacturers work in process inventory is calculated as the raw materials plus labor and production overhead. WIP beginning WIP inventory manufacturing costs COGM. The value of your businesss inventory is constantly changing as products are received assembled stored and.

Some inventory might have one stage of machining done and other inventory might have all. The formula for this is as follows. There are two types of.

For example suppose a companys beginning. This product value is important for financial reporting.

Process Costing Cost Of Ending Wip And Units T O Youtube

Wip Inventory Definition Examples Of Work In Progress Inventory

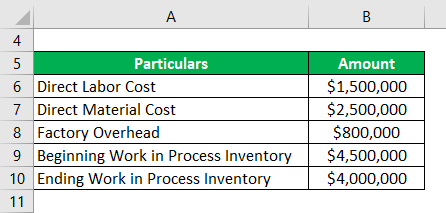

Cost Of Goods Manufactured Formula Examples With Excel Template

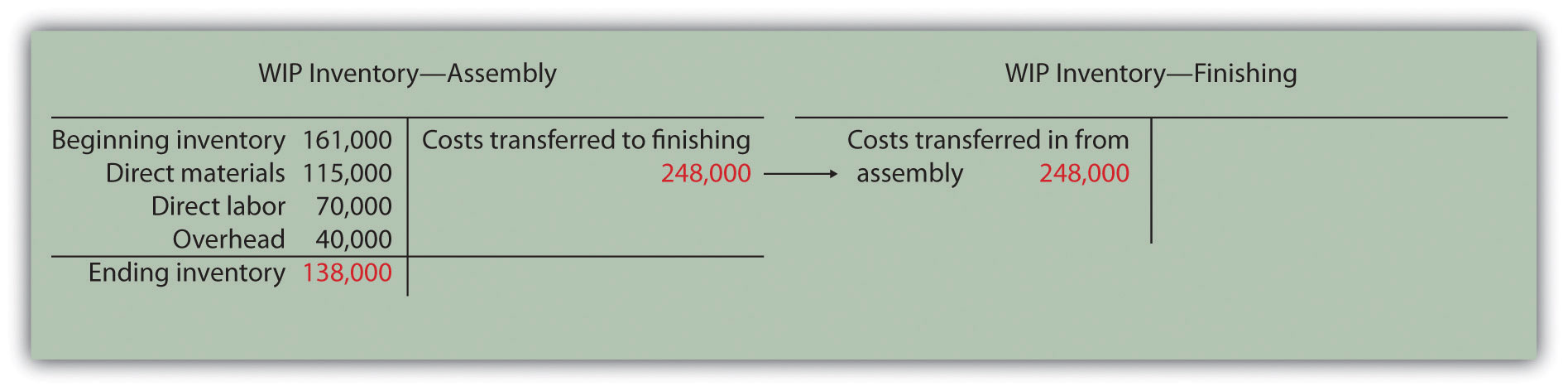

8 4 Tracing The Flow Of Costs In Job Order Financial And Managerial Accounting

:max_bytes(150000):strip_icc()/calculate-cash-conversion-cycle-393115-v4-JS2-869f1dcda7b744abb1b815b2fd25c031.png)

Calculating The Cash Conversion Cycle Ccc

Work In Process Wip Inventory Guide Formula To Calculate

Work In Process Wip Inventory Youtube

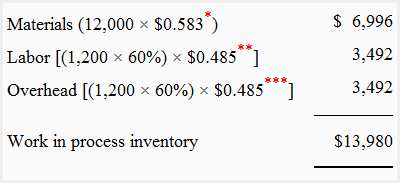

Problem 2 Cost Assigned To Work In Process Inventory Accounting For Management

Work In Process Wip Inventory Definition How It Works Formula

How Product Costs Flow Through Accounts

Solved South Marine Company Calculation Of Cost Of Goods Manufactured For Current Year Beginning Work In Process Inventory Plus Manufacturing Cost Course Hero

:max_bytes(150000):strip_icc()/TermDefinitions_Inventory_finalv1-58cba1b0f047427a87db192e10a93f7c.png)

What Is Inventory Definition Types And Examples

Wip Inventory Formula And Calculator Step By Step

Chapter 16 Introduction To Managerial Accounting Ppt Video Online Download

How To Calculate Cost Of Goods Manufactured With Examples Indeed Com

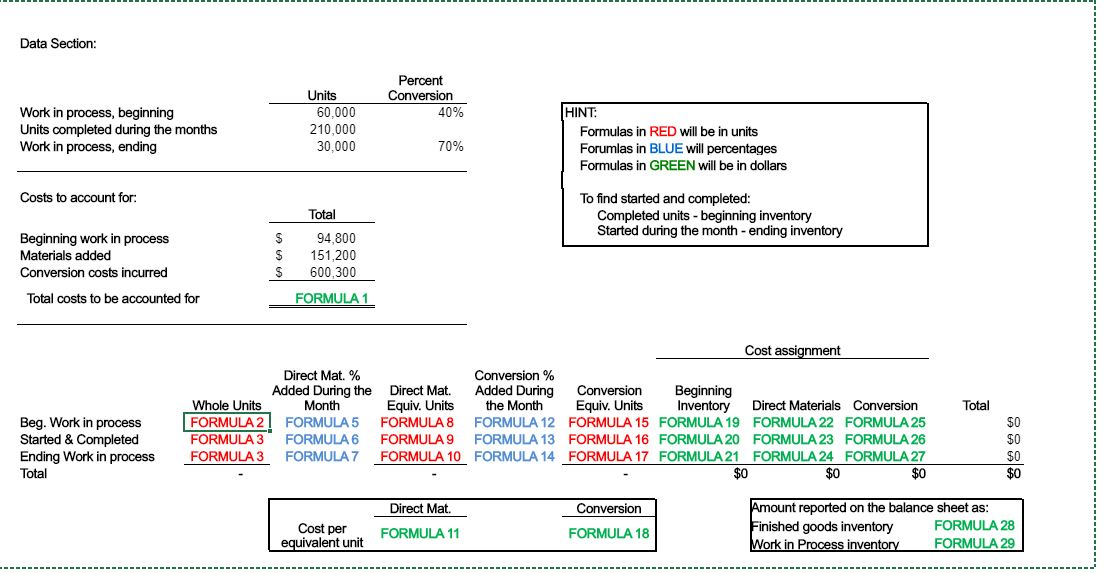

Solved Data Section Percent Conversion 40 Hint Work In Chegg Com